Beyond Standard: The Special-Shaped Lock Advantage

A standard padlock serves a functional purpose, but it rarely tells a story or reinforces a brand. There are situations where a security device needs to do more than just lock; it needs to represent an identity, fit a unique space, or serve as a tangible symbol. This is where the concept of a Special-shaped Lock becomes relevant. Unlike conventional designs, these locks are born from a collaborative process between a client's vision and a manufacturer's expertise.

The journey of creating a unique lock begins with an idea. A company may want a padlock shaped like its logo for a promotional campaign, a municipality might need a uniquely shaped lock for historic property gates, or a retailer could desire a heart-shaped lock for a decorative display. Bringing this idea to life is the role of a professional Custom Special-shaped Lock Manufacturer. The early step is always a detailed consultation. This conversation focuses on understanding the intended use, the desired aesthetic, and the functional requirements. It is here that initial sketches or concepts are discussed, and the feasibility of the design is explored from an engineering perspective.

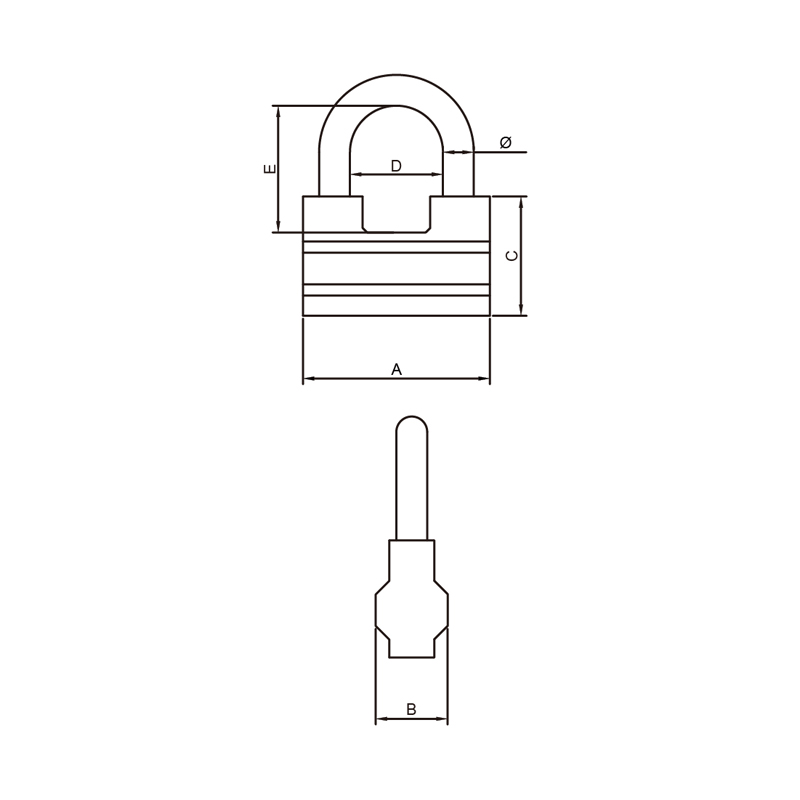

Once the concept is clear, the technical phase begins. Using 3D modeling software, designers create a digital prototype of a special-shaped Lock. This model allows everyone to visualize the product in detail, assessing proportions, structural integrity, and how the internal locking mechanism will integrate with the non-standard exterior. For a custom-shaped lock Manufacturer, this step is crucial for identifying potential production challenges before any metal is cut. A physical prototype is often produced next, typically through CNC machining or 3D printing. Holding this sample provides the client with a tangible sense of the final product's look and feel.

With the prototype approved, the focus shifts to manufacturing. The creation of a special-shaped Lock often requires custom molds or specialized tooling for die-casting or forging the lock body. This investment ensures that every unit in the production run maintains the same precise dimensions and detail. Materials are selected based on the lock's application; brass may be chosen for its corrosion resistance and machinability, while stainless steel might be selected for its strength. Throughout production, stages like precision machining, polishing, and surface treatment (such as electroplating or powder coating) are meticulously managed to achieve the desired quality and finish.

The final stages involve assembly and rigorous testing. Each component, from the custom-shaped body to the standard internal cylinder, is assembled by hand. The finished Special-shaped Lock then undergoes a series of checks for durability, key smoothness, and tensile strength. This ensures that the artistic form does not compromise the security function. A reliable Custom Special-shaped Lock Manufacturer views this quality control as non-negotiable, delivering a product that is both visually distinctive and mechanically dependable.

Choosing to develop a special-shaped Lock is a step towards transforming a generic security item into a branded asset or a specialized tool. It demonstrates an attention to detail that standard products cannot offer. By partnering with an experienced Custom Special-shaped Lock Manufacturer, businesses and organizations can secure their assets with a product that is uniquely theirs, adding a layer of distinction and value that resonates with their specific audience.

English

English Español

Español 中文简体

中文简体 русский

русский