How Do You Choose Between an Iron Padlock and a Brass Padlock?

Selecting the right padlock involves evaluating both security needs and environmental conditions. A sturdy Iron Padlock is a solid choice for general applications like storage units, gates, and indoor lockers. It is cost-effective and can handle frequent use, but its corrosion resistance can vary depending on the coating and environment.

For outdoor or marine environments, a Brass Padlock is often preferred. Brass offers natural corrosion resistance, which keeps the lock functioning smoothly even in humid or salty conditions. This makes a Custom Iron Padlock Brass Padlock an ideal solution for facilities that need both durability and reliability.

When considering a padlock, focus on:

- Shackle strength and thickness

- Locking mechanism type (single or double locking)

- Anti-pick and anti-drill features

- Key system quality

A Custom Iron Padlock Brass Padlock with these features ensures both convenience and dependable protection.

Iron Padlock vs. Brass Padlock: Material Considerations

Understanding material differences helps in choosing the right lock.

Iron Padlock:

- Pros: Strong, affordable, suitable for indoor or temporary security

- Cons: Can rust over time in humid or coastal environments

- Applications: Toolboxes, warehouse gates, lockers

Modern production techniques, such as zinc plating or powder coating, significantly reduce surface corrosion. Yet, in goodly wet or salty environments, iron may still need maintenance.

Brass Padlock:

- Pros: Corrosion-resistant, smooth key operation, long-lasting

- Cons: Higher cost compared to iron

- Applications: Outdoor gates, marine equipment, high-traffic areas

A Custom Iron Padlock Brass Padlock can combine these advantages, using iron for structural strength and brass components for the cylinder to improve corrosion resistance and key performance.

Key Features to Look for in a Padlock Manufacturer

Working with a reliable factory ensures consistent quality and durability.

Material and Craftsmanship:

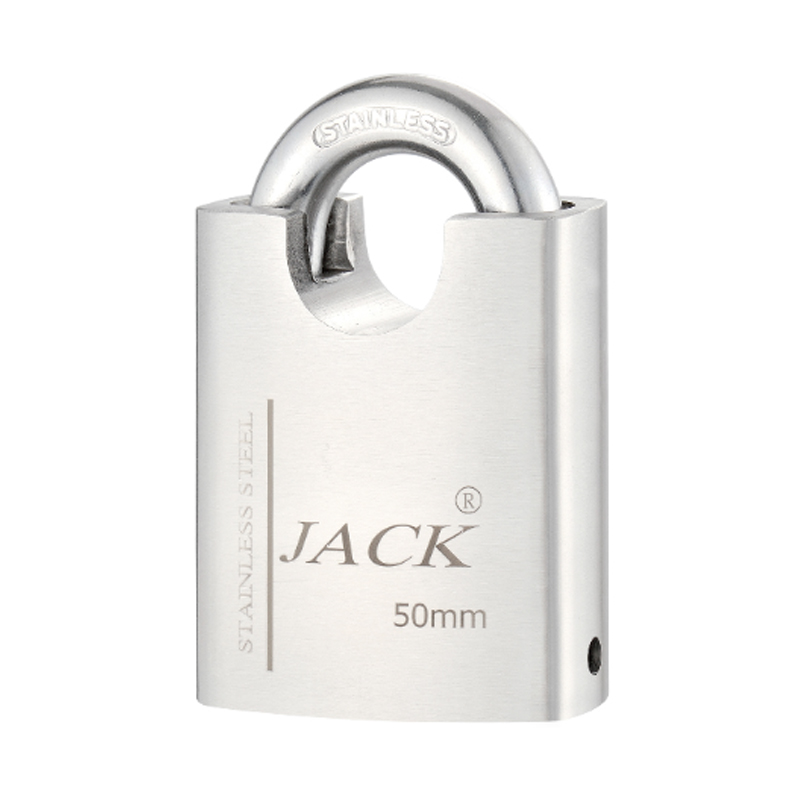

High-quality padlocks use precision-cast brass bodies, hardened steel shackles, and CNC-machined lock cylinders. These details affect longevity, key smoothness, and anti-theft performance.

Practical Applications of Custom Iron Padlock Brass Padlock

Businesses and industrial facilities often face different security challenges:

- Outdoor Gates and Fences:

Brass components help resist weather effects, while iron provides structural strength.

- Tool Storage:

Indoor iron padlocks are cost-effective and sturdy for daily use, ideal for workshops and warehouses.

- Marine Equipment:

Exposure to saltwater accelerates corrosion. Brass cylinders in a Custom Iron Padlock Brass Padlock maintain smooth operation even under harsh conditions.

Temporary Sites or Construction Areas:

Iron padlocks provide quick deployment and cost savings while still offering reasonable security.

By matching the lock type to its intended application, businesses avoid premature wear and reduce replacement costs.

Choosing the Right Partner

When sourcing Iron Padlock or Brass Padlock products, factory reliability is key:

- Inspect manufacturing quality and materials

- Verify testing standards

- Confirm customization capabilities

- Check after-sales service

Working with an experienced Custom Iron Padlock Brass Padlock manufacturer ensures your locks meet functional and environmental requirements.

A Custom Iron Padlock Brass Padlock combines material advantages, manufacturing quality, and tailored features to provide reliable security. Choosing the right padlock requires careful consideration of the environment, usage, and design requirements. Partnering with a professional factory guarantees that every lock delivers consistent performance, smooth operation, and long-term durability, whether for industrial, commercial, or outdoor applications.

English

English Español

Español 中文简体

中文简体 русский

русский