Can Custom Iron Padlock Brass Padlock Handle Long-Term Weather Exposure?

Security needs continue to evolve as buyers demand locking solutions that are durable, stable in real use, and adaptable to different environments. Many distributors and brand owners now look for products that solve specific user pain points rather than simply offering a standard lock. This is where the flexibility of a Custom Iron Padlock Brass Padlock becomes valuable. By customizing materials, structure, and key systems, factories can provide solutions that match exact commercial requirements instead of relying on generic products.

One of the biggest concerns among buyers is long-term reliability. A lock may look solid at an early glance, yet its internal structure determines how it performs after months or years. Iron padlocks are widely chosen for general use thanks to their strength and attractive pricing. Brass padlocks, on the other hand, offer stable performance in humid or outdoor environments. When selecting between the two, buyers often struggle with balancing cost and lifespan. In cases where humidity, rain, or marine conditions are present, a brass option usually delivers better durability. This is why many businesses choose a Custom Iron Padlock Brass Padlock design, combining iron for strength and brass for smoother internal operation.

1. Material Choice and Long-Term Durability

Industrial buyers consistently worry about corrosion and environmental impact. Iron padlocks with modern coatings offer strong performance for indoor applications such as toolboxes, lockers, and warehouse units. Still, once exposed to heavy moisture, iron may develop surface oxidation. Brass padlocks react differently. Brass resists corrosion better and maintains stable key rotation without sticking, even after long exposure to outdoor conditions. When factories build a Custom Iron Padlock Brass Padlock, they often combine the favorable properties of both materials to create a balanced option for distributors serving mixed-use markets.

2. Structural Features That Matter in Real Use

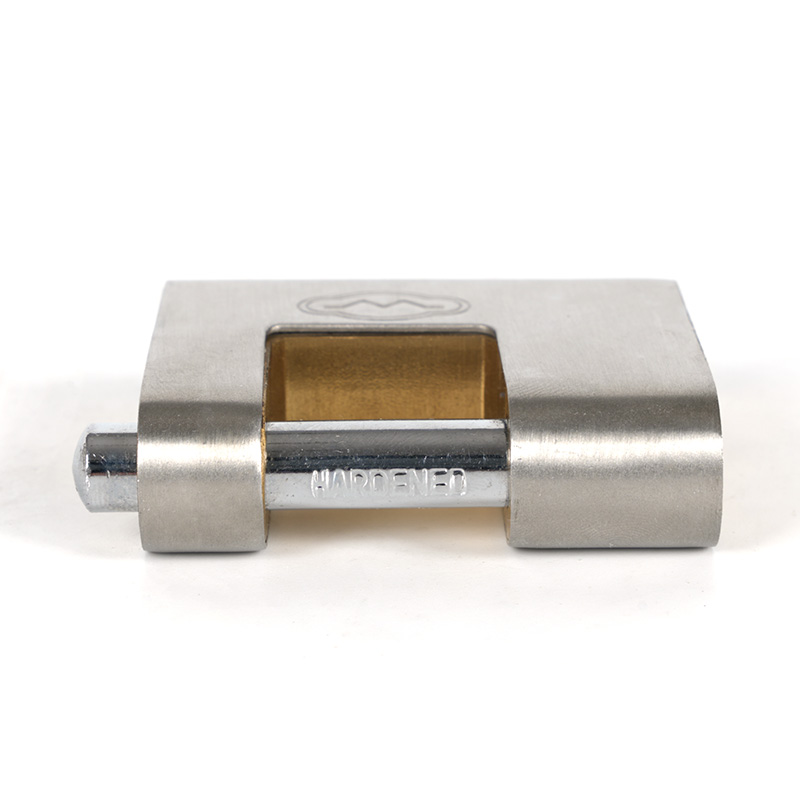

A strong padlock is more than its body material. Buyers care deeply about internal mechanisms because these directly influence tamper resistance and daily usability. Hardened shackles, brass cylinders, and double-locking structures help prevent forced entry and maintain stability across different environments. Many commercial users—such as logistics companies, facility managers, and rental storage operators—prefer a lock that stays consistent even after thousands of key rotations. With a Custom Iron Padlock Brass Padlock, manufacturers can adjust the cylinder precision, key combination range, and shackle hardness to support specific application scenarios.

Customization is equally important for brand identity. Distributors and wholesalers often request engraved logos, unique colors, or dedicated packaging formats. Factories capable of helping OEM and ODM services clients build market differentiation. A capable padlock factory offers detailed material specifications, full inspection processes, and sample development for new projects. These practices allow buyers to reduce product risk while strengthening their brand credibility.

A dependable factory is not defined only by its product catalog. Buyers evaluate production capacity, craftsmanship, and quality control systems. Salt spray testing, key durability tests, and tensile strength checks are common procedures that responsible factories follow. This gives distributors confidence that their lock will hold up under real-world use. When working with Custom Iron Padlock Brass Padlock manufacturers, buyers expect consistent communication, flexible customization, and stable cycle times. These qualities help support long-term cooperation in competitive markets.

English

English Español

Español 中文简体

中文简体 русский

русский