How Can A Factory Brass Padlock Improve Access Control?

Growing demand for reliable locking solutions has pushed buyers to look beyond appearance alone. Many commercial and residential users now expect padlocks to offer stable performance in different environments while maintaining a clean and professional look. This is why interest in the Factory Brass Padlock category continues to rise. Buyers appreciate materials that stay steady over time, especially in humid or outdoor settings where ordinary locks struggle.

A Brass Padlock is known for its corrosion resistance and clean golden tone, making it suitable for both visual appeal and functional use. Brass works well in climates with humidity, salt, or wide temperature shifts. This combination of durability and appearance is a key reason buyers consider partnerships with factories capable of producing stable and consistent brass lock models.

1. Material Strength and Environmental Resistance

One of the biggest concerns among distributors is how well a lock performs after months of exposure to outdoor air, rain, or seaside conditions. Brass resists oxidation naturally, which means the internal cylinder stays smooth even after repeated use. Unlike materials that need heavy coatings to deal with moisture, brass maintains a stable surface. This is helpful for buyers who distribute locks to coastal regions, construction sites, or outdoor storage facilities. A Factory Brass Padlock is valued because it continues functioning with minimal maintenance, making it a practical choice for clients needing predictable long-term performance.

2. Appearance and Brand Positioning

Padlocks may seem like simple hardware pieces, yet appearance still matters in retail stores, decorative gates, or commercial entrances. Brass offers a warm, clean look that supports higher-end branding. Distributors serving retail chains or renovation markets often request brass options for this reason. The material projects a sense of quality without appearing overly technical. When working with a factory that produces Brass Padlock models, buyers can request custom colors, engraved logos, or packaging that fits their brand direction. This level of flexibility helps them differentiate their catalog and appeal to varied customer preferences.

3. Durability and Long-Term Use

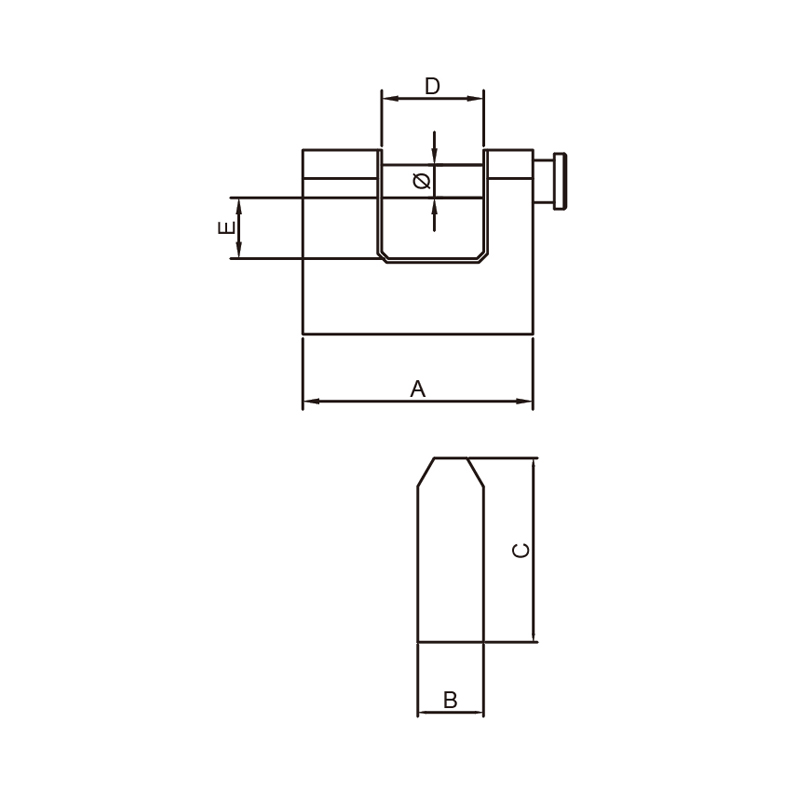

Durability is another core concern for industries that rely on frequent lock and unlock cycles. Brass is strong enough to handle daily wear while maintaining stable internal alignment. A durable cylinder reduces the chance of key jamming or surface deformation. This is valued in applications such as rental storage, warehouse access, or equipment control. When buyers look for a Factory Brass Padlock, they often ask about shackle material, machining precision, and how the lock performs after thousands of cycles. Factories familiar with brass machining can provide consistent quality, giving distributors confidence in long-term product stability.

Weather resistance also matters across different climates. Brass handles cold, heat, and moisture without losing structural integrity. This makes a Brass Padlock suitable for year-round use, reducing the replacement cycle for customers. A steadier product means lower service claims and a stronger reputation for distributors.

4. What Buyers Expect From a Factory Partner

A factory that produces brass padlocks must offer more than standard catalog items. Buyers expect clear communication, consistent machining quality, and material transparency. They also look for the ability to support custom locking systems, color finishes, or branded accessories. This helps them create unique versions of a Factory Brass Padlock tailored to their target markets.

Quality control plays a central role in the decision-making process. Buyers typically ask about salt spray testing, cylinder smoothness checks, and durability tests. These steps help verify the stability of each Brass Padlock model before mass production. As markets grow more competitive, distributors prefer factories that can adapt quickly, offer small customization runs, and provide flexible cycle times.

English

English Español

Español 中文简体

中文简体 русский

русский