Why Is Key Security Important In An Iron Padlock System?

Iron padlocks have long been valued for their strength, affordability, and practicality. Their primary appeal lies in durability—they can withstand rough handling, frequent use, and varying weather conditions. For industrial environments, choosing the right Iron Padlock means considering operational frequency, exposure to moisture, and the level of security required.

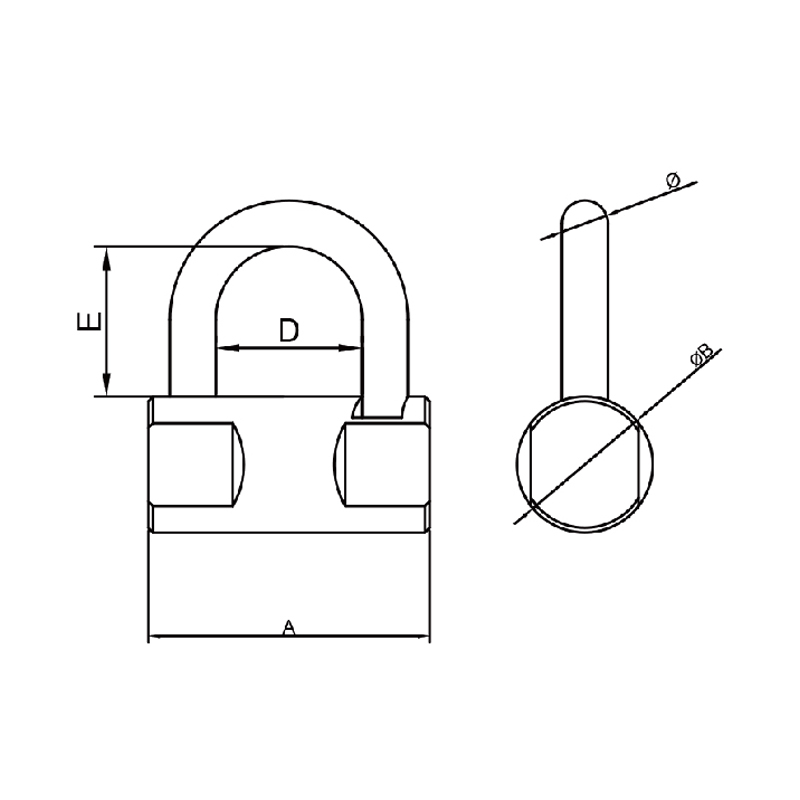

A Factory Iron Padlock is typically engineered with these use cases in mind. Its shackle thickness, internal cylinder precision, and body reinforcement are designed to cope with repeated opening and closing, while resisting external force. This approach allows locks to maintain functional reliability over time, especially in demanding industrial or commercial applications.

Material Choice and Corrosion Resistance

The core material of an Iron Padlock is critical to performance. Iron is inherently strong, but it can rust if left unprotected. Manufacturers often apply galvanization, powder coating, or electroplating to improve corrosion resistance. These coatings extend the life of the padlock in humid, coastal, or outdoor settings.

While raw iron is cost-effective, proper surface treatment is essential for long-term reliability. A Factory Iron Padlock combines sturdy iron with protective finishes to balance affordability with durability. For users, understanding these material properties helps in selecting locks that remain operational without frequent replacements or repairs.

Internal Design and Key Operation

A padlock's internal mechanism plays an important role in smooth operation and security. Precise machining of the cylinder and shackle interface reduces friction, ensures consistent key rotation, and prevents premature wear.

Some Factory Iron Padlock models include replaceable cylinders, anti-pick pins, or double-locking mechanisms. These features not only enhance security but also simplify maintenance, which is especially valuable in industrial settings where locks are exposed to dust, dirt, or occasional rust particles.

Ease of use is another factor. Industrial personnel benefit from locks that open and close reliably without requiring excessive force, even after months of use. Correctly designed internal mechanisms maintain this functionality while protecting the lock from unauthorized access.

Maintenance Practices for Longevity

Even the robust Iron Padlocks require routine care. Regular cleaning, light lubrication, and inspection for rust or debris help maintain smooth operation. In outdoor applications, protective covers or shaded installation reduce moisture exposure and slow corrosion.

Users should apply anti-rust oil or silicone-based lubricants to the keyway every few months. Cleaning the shackle and removing dust or sand from the cylinder prevents sticking and ensures keys turn freely. Proper maintenance allows an Iron Padlock to provide reliable security for years, complementing the quality provided by a professional factory.

Emergency Handling and Safe Practices

Emergencies, such as lost keys or jammed locks, are inevitable. A well-designed Factory Iron Padlock can include emergency release structures or replaceable cylinders to address such situations without damaging the lock or the protected property.

For industrial or commercial settings, keeping spare keys or a master key system in a secure location is recommended. Attempting to force the lock open can permanently damage the padlock, reducing its effectiveness and causing unnecessary costs. Manufacturers advocate safe unlocking methods and routine inspection to prevent emergencies and prolong padlock life.

By combining robust manufacturing, careful material selection, precise design, and proper maintenance, every Iron Padlock can deliver reliable performance. This balance of factory quality and user care makes it a dependable solution for industrial, commercial, and everyday security needs.

English

English Español

Español 中文简体

中文简体 русский

русский