Established in 1992, Zhejiang Pujiang Wushi Lock is a set of design, research and development, production, trade professional locks enterprise.

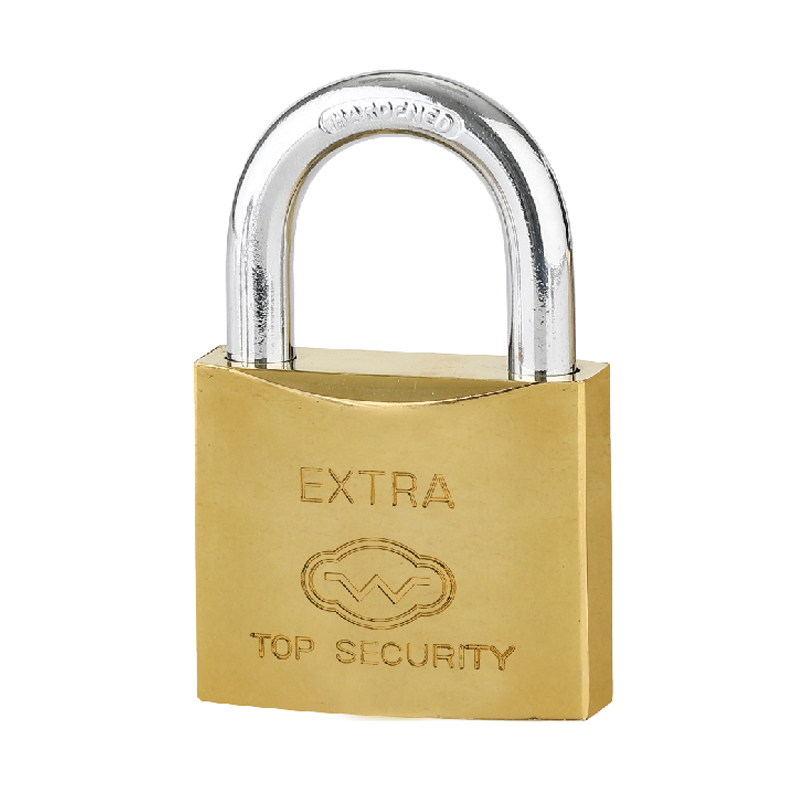

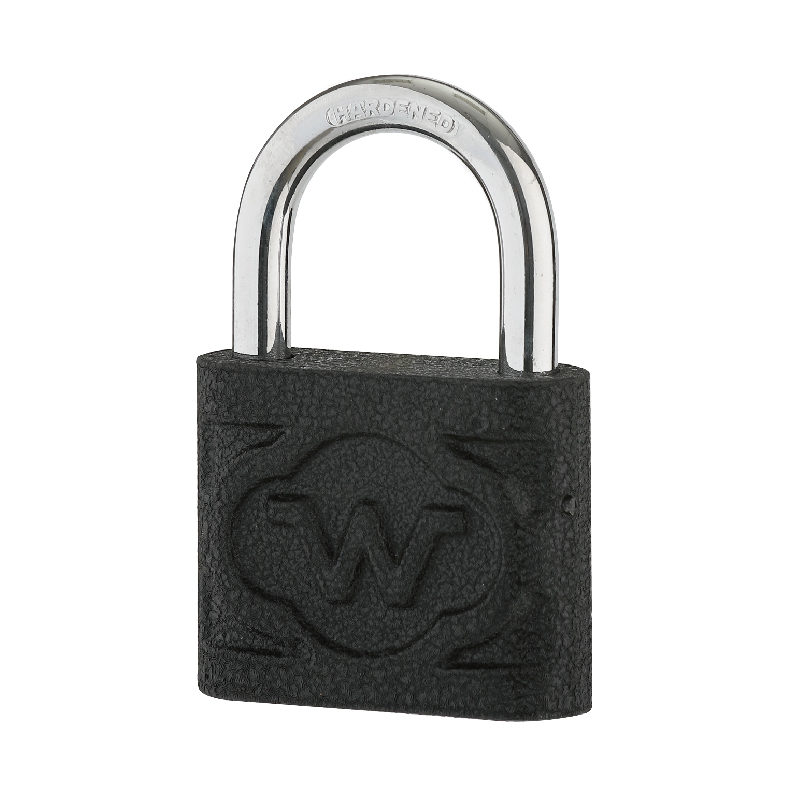

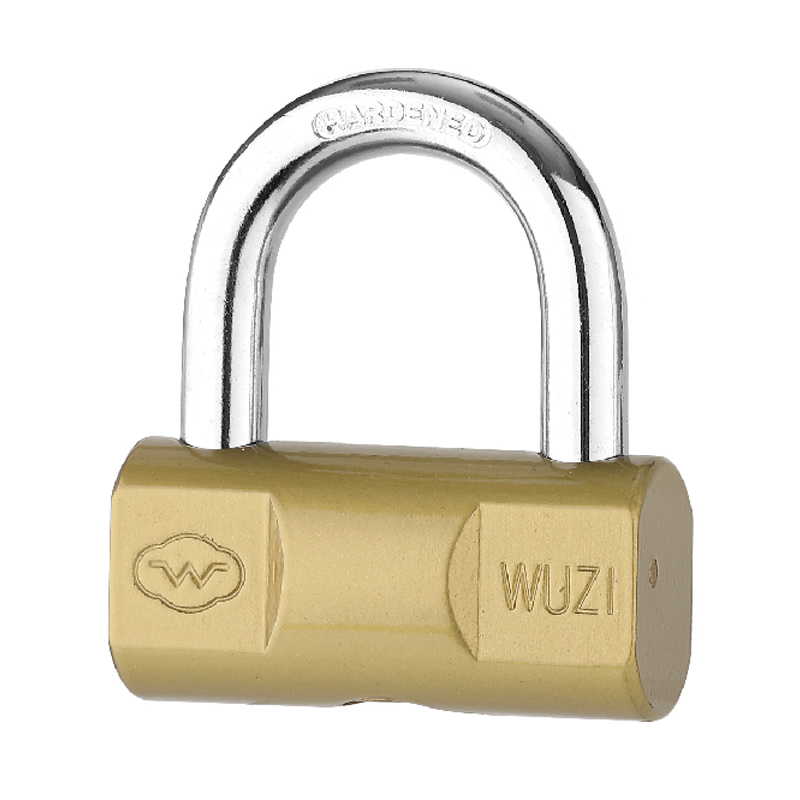

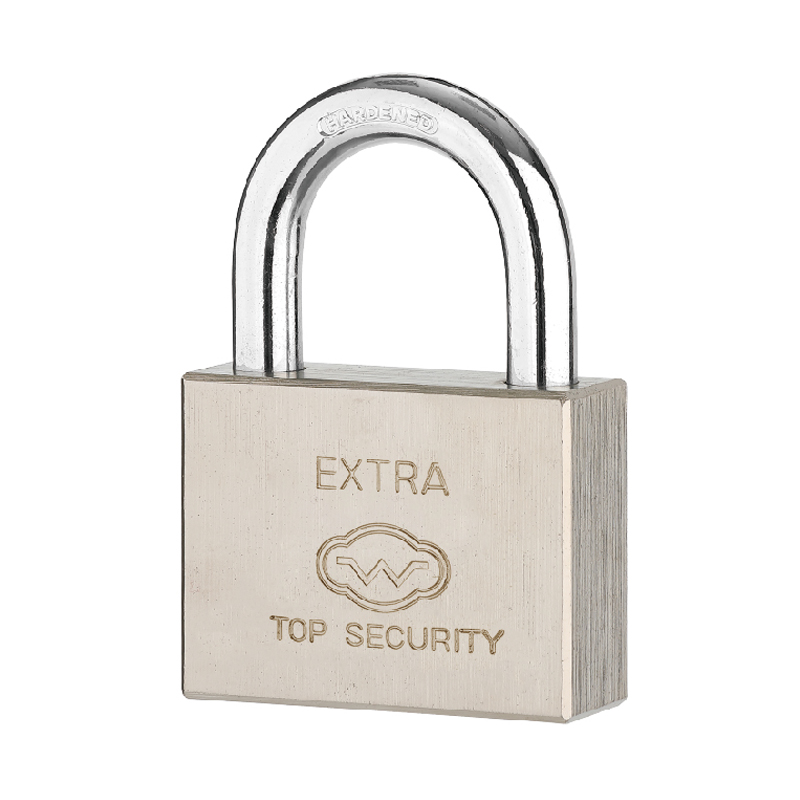

As a professional custom Iron Padlock manufacturer and Iron Padlock factory in China, our Company mainly manufactures copper padlocks, iron padlocks, steel padlocks, aluminum padlocks, zinc padlocks, door locks and more than 300 other types of products that sell well in the domestic market and are exported to Russia, Europe and the United States, Southeast Asia, the Middle East and other international markets.

Take step and get in touch with us today.

1.The Impact of Rust on Iron Padlocks

From the perspective of a professional Iron Padlock manufacturer, rust is one of common issues that affects the performance and longevity of padlocks. When an Iron Padlock begins to rust, it doesn't just change in appearance—the internal and external functions are also compromised. Rust forms when iron reacts with moisture and oxygen, cause oxidation that weakens the metal surface. Over time, this corrosion can cause the shackle to stick, the keyhole to jam, and the locking mechanism to fail.

A rusted Iron Padlock often loses its strength and becomes vulnerable to breakage or forced entry. In addition, rust particles can accumulate inside the cylinder, preventing smooth key rotation and reducing security precision. That's why as a manufacturer, we always recommend proper coating and protective finishes, such as electroplating or powder coating, to enhance corrosion resistance. Regular maintenance and the use of lubricants are also essential preventive measures to maintain the performance of your Iron Padlock in different environments.

2.How to Use and Maintain Iron Padlocks Properly?

As a professional Iron Padlock factory, we emphasize that correct usage and regular care are ways to extend the life of a padlock. When using an Iron Padlock, it's important to ensure that the shackle and lock body remain clean and dry. Avoid exposing the lock to prolonged rain or direct sunlight, especially in coastal or humid environments where salt air accelerates rust formation.

For maintenance, apply a light coat of anti-rust oil or silicone lubricant every few months. This not only reduces friction inside the lock cylinder but also creates a barrier against moisture. If the Iron Padlock is used outdoors, we suggest covering it with a protective cap or placing it in a shaded area to minimize weather exposure.

Cleaning should also be part of your routine. Use a soft brush or compressed air to remove dust, sand, or other particles from the keyhole. When the key becomes hard to turn, do not force it—instead, apply a lubricant into the keyway and gently rotate the key to restore smooth motion. With proper care, a well-made Iron Padlock can last for many years while maintaining its strength and functionality.

3.How to Handle Emergencies: Unlocking an Iron Padlock Safely?

Even though Iron Padlocks are designed to provide strong security, there may be emergency situations—such as losing the key, forgetting the combination, or having a jammed lock—where you need to unlock it quickly. From a manufacturer's perspective, we always encourage users to prioritize safe and lawful solutions. method is to contact a professional locksmith who can open the Iron Padlock without damaging the lock body or the object it protects.

If immediate access is needed, lubricating the keyhole and tapping gently on the body can sometimes release a stuck mechanism caused by rust or debris. For industrial users or property managers, having a master key system or spare keys kept securely is a smart preventive measure. Some high-end Iron Padlocks are designed with replaceable cylinders or emergency release structures that allow easy servicing when needed.

However, forcibly breaking or prying open a padlock should be the last resort, as it permanently damages the product and may pose safety risks. As a responsible Iron Padlock manufacturer, we strongly advocate proper key management and periodic inspection to prevent such emergencies in place.

Rust prevention, correct maintenance, and responsible emergency handling are all key to ensuring the reliability of an Iron Padlock. From the manufacturing viewpoint, we design our Iron Padlocks with robust coatings, precision machining, and durable structures to resist wear and corrosion. Yet, the user's care also plays a decisive role in maintaining performance. By combining quality manufacturing and good maintenance habits, every Iron Padlock can continue to deliver dependable protection and long service life in both industrial and daily applications.

English

English Español

Español 中文简体

中文简体 русский

русский