Established in 1992, Zhejiang Pujiang Wushi Lock is a set of design, research and development, production, trade professional locks enterprise.

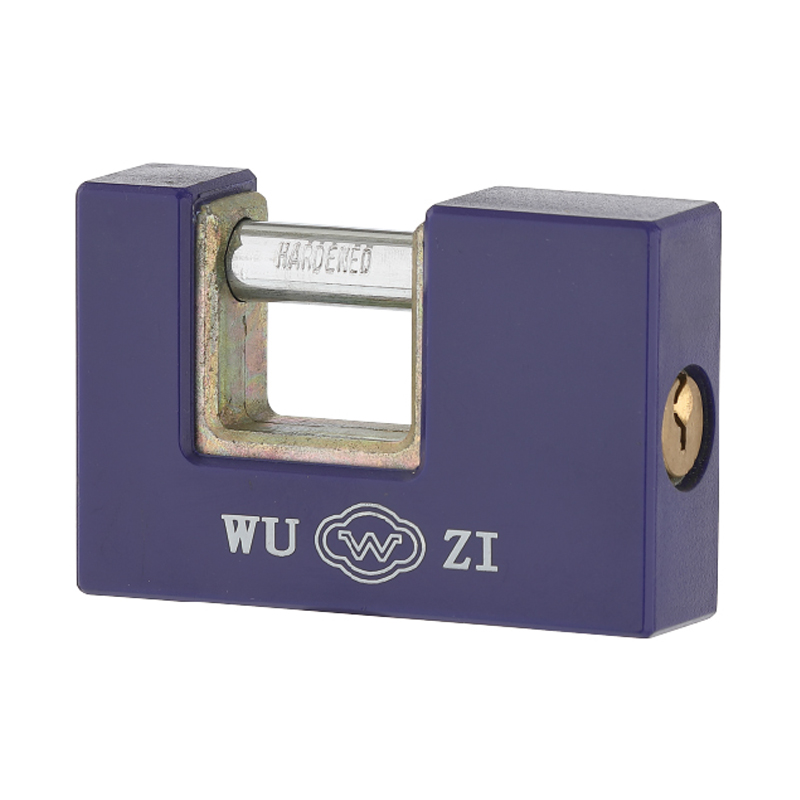

As a professional custom Zinc Alloy Padlock manufacturer and Zinc Alloy Padlock factory in China, our Company mainly manufactures copper padlocks, iron padlocks, steel padlocks, aluminum padlocks, zinc padlocks, door locks and more than 300 other types of products that sell well in the domestic market and are exported to Russia, Europe and the United States, Southeast Asia, the Middle East and other international markets.

Take step and get in touch with us today.

1.Is Zinc Alloy Suitable for Making Padlocks?

From the standpoint of a Zinc Alloy Padlock manufacturer, zinc alloy is an outstanding material for producing padlocks due to its balance of strength, corrosion resistance, and manufacturability. Unlike pure metals, zinc alloy is composed of zinc mixed with small amounts of aluminum, copper, and magnesium, giving it improved hardness and dimensional stability. This makes it particularly suitable for complex lock body designs that require fine detail and smooth surfaces.

A Zinc Alloy Padlock also benefits from the alloy's natural resistance to corrosion. When exposed to air, zinc forms a protective oxide layer that prevents rusting—making it ideal for indoor and light outdoor use. Moreover, zinc alloy has a relatively low melting point, which allows manufacturers to use die-casting technology for precision shaping. This process ensures consistent product quality and efficient mass production, making Zinc Alloy Locks both affordable and reliable for general security applications such as luggage, cabinets, and toolboxes.

2.Is Zinc Alloy a Cheap Metal? What Are Its Material Characteristics?

In the eyes of a professional Zinc Alloy Lock manufacturer, zinc alloy is not necessarily a “cheap” metal, but rather a cost-effective and versatile one. Compared to high-end materials like stainless steel or brass, zinc alloy offers significant savings in material and processing costs, yet still provides adequate strength for medium-security use.

The key characteristics of zinc alloy include:

- Outstanding Castability: It flows easily in molten form, allowing the production of intricate lock bodies and decorative shapes.

- Good Surface Finish: Zinc alloy can achieve a smooth, shiny surface suitable for plating or coating. Many Zinc Plated Steel Padlocks use a zinc coating for its bright, corrosion-resistant finish.

- Moderate Strength and Weight: It is stronger than plastic or aluminum but lighter than steel, making it ideal for portable padlocks.

- Corrosion Resistance: The material's natural oxide layer provides basic rust prevention, and additional plating can further improve weather resistance.

While Zinc Alloy Locks are more affordable than steel or brass locks, they maintain impressive durability and visual appeal, which is why many manufacturers, including our factory, choose this alloy for consumer-grade and decorative security products.

3.How Durable Are Zinc Alloy Padlocks?

From a Zinc Alloy Padlock factory's perspective, the durability of zinc alloy locks largely depends on their application environment and surface treatment. In indoor or semi-outdoor conditions, these locks can last for many years without significant wear or corrosion. The die-cast body is solid and impact-resistant, providing good protection against tampering or accidental drops.

For improved durability, many Zinc Alloy Padlocks are paired with hardened steel shackles or use Zinc Plated Steel Padlock designs, combining the lightweight corrosion resistance of zinc with the tensile strength of steel. When coated with chrome, nickel, or powder finishes, zinc alloy locks gain additional protection from humidity and oxidation.

However, in extremely harsh outdoor or marine environments, Zinc Alloy Locks may not perform as well as stainless steel or brass models due to long-term exposure to moisture and salt. In such cases, we recommend using zinc alloy padlocks with thick electroplating or applying a clear protective sealant.

Zinc Alloy Padlocks offer a practical balance between cost, aesthetics, and performance. Zinc alloy is not merely a low-cost material—it is a versatile and durable option that supports precision casting, corrosion protection, and decorative finishes. When combined with steel components, Zinc Plated Steel Padlocks and Zinc Alloy Locks can provide outstanding everyday security. From a manufacturer's perspective, zinc alloy remains one of efficient materials for producing stylish, long-lasting padlocks that meet both functional and economic demands.

English

English Español

Español 中文简体

中文简体 русский

русский