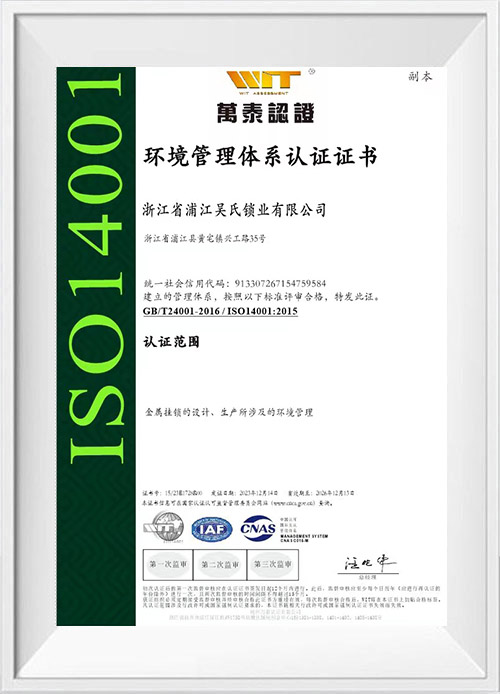

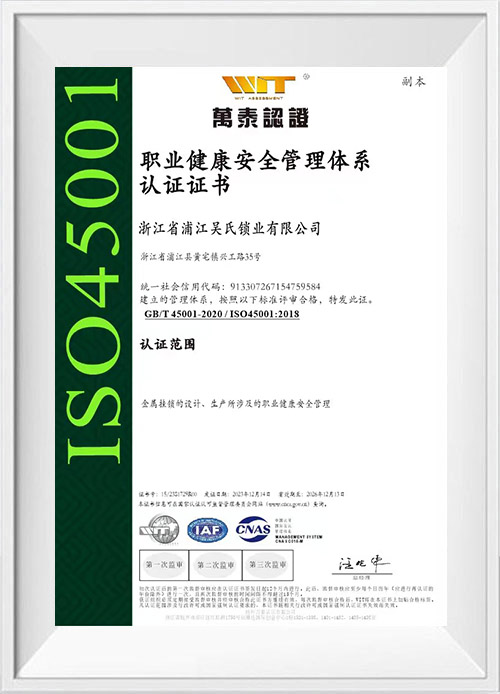

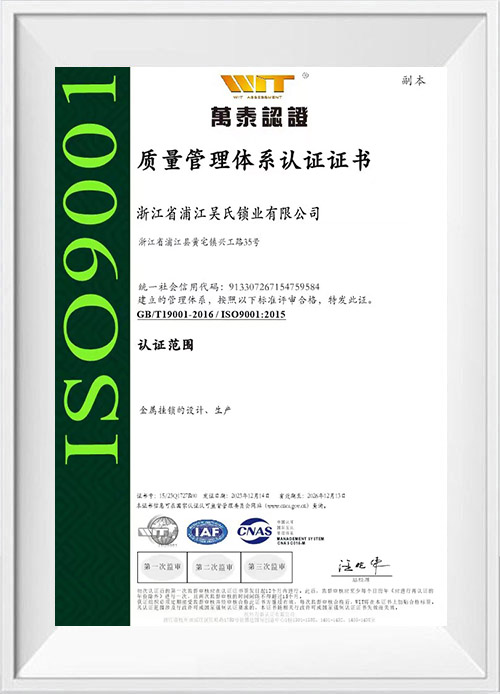

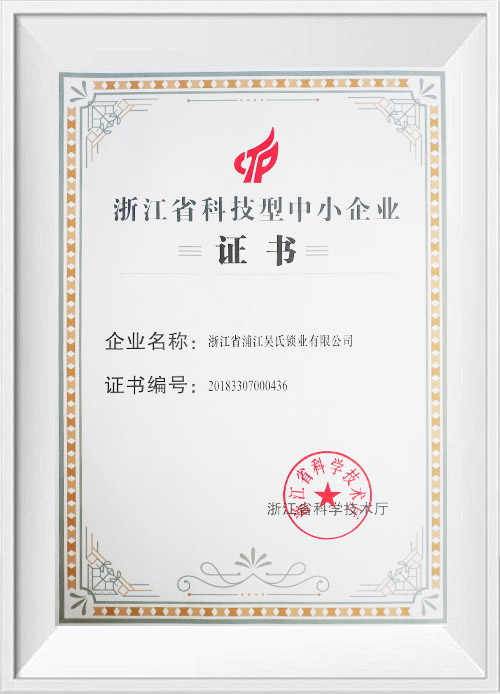

Established in 1992, Zhejiang Pujiang Wushi Lock is a set of design, research and development, production, trade professional locks enterprise.

As a professional custom Steel Padlock manufacturer and Steel Padlock factory in China, our Company mainly manufactures copper padlocks, iron padlocks, steel padlocks, aluminum padlocks, zinc padlocks, door locks and more than 300 other types of products that sell well in the domestic market and are exported to Russia, Europe and the United States, Southeast Asia, the Middle East and other international markets.

Take step and get in touch with us today.

1.Typical Shackle Thickness in Steel Padlocks

From the perspective of a Steel Padlock manufacturer, the thickness of the shackle (the U-shaped metal loop) plays a crucial role in determining the lock's strength and resistance to cutting or prying. Typically, the shackle diameter for standard Steel Padlocks ranges from 5mm to 12mm, depending on the size and security level.

Small or medium padlocks designed for lockers, toolboxes, or luggage often feature shackles around 5–7mm thick. Heavy-duty Steel Padlocks, used for gates, warehouses, or industrial containers, can reach 10–12mm or even more. In high-security models, the shackle is made of hardened alloy steel, heat-treated for toughness. This process improves the lock's tensile strength and makes it more resistant to saws and bolt cutters.

As a Steel Padlock factory, we ensure the shackle and lock body are precisely matched to maintain balance between security and usability. Too thin a shackle may be easy to cut, while overly thick shackles might not fit standard latches. That's why proper size selection based on actual application is essential when choosing a Steel Padlock.

2.Are There Uncuttable Steel Padlocks?

From an engineering standpoint, no Steel Padlock is truly “uncuttable,” but certain models are designed to make cutting nearly impossible with conventional tools. These are often marketed as Corrosion Protection Padlocks or Stainless Steel Padlocks, and they incorporate multiple layers of defense.

High-security Steel Padlocks typically use boron-carbide hardened shackles, one of the hardest materials used in padlock production. It's significantly stronger than regular steel and highly resistant to sawing or cutting. Some designs also feature shrouded shackles, where the lock body partially covers the shackle, reducing exposure and making it difficult for bolt cutters to grip.

In addition, Stainless Steel Padlocks designed for outdoor or marine use combine strength with corrosion resistance, ensuring that environmental degradation does not weaken the shackle over time. These advanced locks may not be absolutely unbreakable, but in practical terms, they offer security levels that far exceed standard padlocks. For industrial or security applications, a Corrosion Protection Padlock with a hardened, shrouded shackle is considered deterrent against forced entry.

3.Surface Treatments for Stainless Steel Padlocks

As a professional Stainless Steel Padlock manufacturing factory, we apply various surface treatments to enhance both aesthetics and durability. The surface finish of a Stainless Steel Padlock is not just about appearance—it also contributes to corrosion resistance and longevity.

- Polished Finish: A mirror-polished surface gives the padlock a bright, smooth appearance and helps repel water and dirt. It is commonly used for consumer and decorative locks.

- Brushed or Satin Finish: Provides a subtle, matte texture that hides fingerprints and scratches, ideal for industrial Stainless Steel Padlocks.

- Electrolytic Passivation: This chemical treatment enhances the lock's corrosion resistance by forming a passive oxide layer that protects the stainless steel from rust and oxidation.

- Nickel or Chrome Plating: Often applied on Steel Padlocks for added shine and environmental protection, especially when used in outdoor conditions.

For Corrosion Protection Padlocks, combining stainless steel material with surface treatments such as passivation or special coatings ensures outstanding resistance to saltwater, humidity, and chemical exposure.

The quality and strength of a Steel Padlock or Stainless Steel Padlock depend largely on its material composition, shackle design, and surface treatment. While there's no truly uncuttable padlock, modern Corrosion Protection Padlocks with hardened shackles and advanced finishes provide exceptional security and long-term durability. As a specialized factory, we continue to innovate and manufacture Steel Padlocks that balance performance, protection, and precision for every security need.

English

English Español

Español 中文简体

中文简体 русский

русский